How We Do It

EcoHub’s closed-loop system provides ultimate sustainability™ and the most environmentally healthy collection path ever conceived.

It’s all made possible by EcoHub’s model of circular integration™, which takes in 100% of the waste stream as a resource and manufactures it into new sustainable products that can be resold back into the local community. This entire process occurs in one location, providing the greatest environmental benefit, while creating new opportunities for local communities.

Here’s how we do it.

Garbage is a Resource

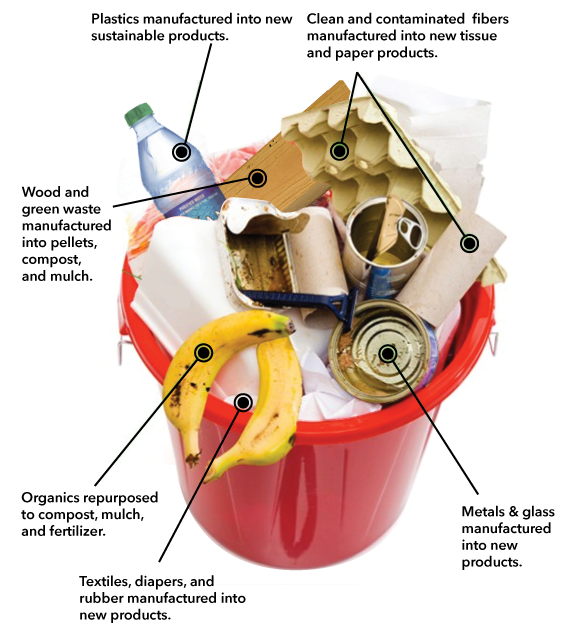

At EcoHub, we view 100% of the waste stream as a valuable resource – and we treat it as such. To us this means that every single piece of food, metal, paper, plastic, green waste, etc. has real economic value. Even items like diapers, rocks, sneakers, and other kinds of waste can be remade into new, sustainable products.

This philosophy is core to everything we do at EcoHub. If our garbage is so valuable, why would we bury it beneath instead of harvesting its potential? Better yet – if there is a way to repurpose 100% of our waste, why separate all our garbage into “recyclables” and “non-recyclables” at all? This is precisely why EcoHub has created the One Bin for AllTM program.

One Bin for All™

Because we view every piece of waste as a valuable resource, we collect all garbage in one single bin, whether it is generated in homes, apartments and condominiums, retail, commercial or industrial customers.

This relieves citizens (and employees of businesses) of the need to separate materials like plastics from regular waste like leftover food or lawn trimmings – eliminating the issue of low participation rates in recycling programs.

At the same time, a reduction in the number of garbage bins on city streets decreases the number of collection trucks needed on the roads. This can help alleviate congestion and noise pollution, while reducing harmful carbon emissions and other airborne pollutants.

Separation & Manufacturing

Smarter Waste™

Once the collection process is complete, all the garbage from the local community is delivered to one of our centralized EcoHub facilities. Here, all of the waste is separated into 30+ reusable feedstock categories utilizing the MaxDiverter™ and VictaSort™ – state of the art, multi-patented systems that automate the separation processes for residential and commercial waste and enable EcoHub to process everything from 1-Bin™, right on site.

Once separated and recovered, we utilize proven, commercially operational technologist repurpose and manufacture every possible resource into new sustainable products. All manufacturing is done directly on the same site, under strict standards that ensure no effluence or harmful pollutants are emitted in the process. Keeping all manufacturing on site cuts back further on greenhouse gas emissions by reducing vehicle travel, while also ensuring all of the resources from one area stay and benefit local community.

Closing the Loop –

Back to the Community

When all is said and done, finished products are produced and delivered right back to the community where they were generated. From there they can be resold, reused, and eventually returned back to EcoHub to begin the process again.

The result of this entire process is the creation of hundreds of new jobs, a dramatic reduction in greenhouse gas emissions, millions of dollars of economic value, and the world’s first truly zero-waste management system that keeps all resources in local communities.

This closed-loop, circularly integrated system is the ultimate form of sustainability and the most environmentally beneficial collection and processing path ever conceived. Did we mention something about the start of an environmental revolution?

Granada, Spain MaxDiverter™ v1.5

Oslo, Norway - MaxDiverter™ v2.0